EPOXY RESIN-10801kg HARDENER 500gm

Price 3000 INR/ Piece

MOQ : 10 Kilograms, ,

EPOXY RESIN-10801kg HARDENER 500gm Specification

- Material

- Other

- Adhesive Type

- Other

- Other Names

- EPOXY RESIN

- Grade

- Industrial Grade

- Purity

- 100%

- Application

- The surface to be resined should be thoroughly clean and dry. For this epoxy system the mixing ratio by weight is 2 parts of epoxy resin (part A) and 1 part of hardener (part B) (A:B=2:1). Mix part A and part B together thoroughly and apply to the stone for resining, netting or other correct application. The surface can be polished after 24 hours according to the ambient temperature (refer to technical data sheet). The product will not harden below 10C-15C (50-59F). Keep away from heat and sunlight.

- Color

- Transparent

- Physical State

- Liquid

EPOXY RESIN-10801kg HARDENER 500gm Trade Information

- Minimum Order Quantity

- 10 Kilograms, ,

- Payment Terms

- Cash on Delivery (COD), Cheque

- Supply Ability

- 1000 Kilograms, , Per Day

- Delivery Time

- Days

- Packaging Details

- We Use carton Boxes For packaging, Wooden Crate Cost Extra Charges.

About EPOXY RESIN-10801kg HARDENER 500gm

Experience the exclusive EPOXY RESIN-10801kg paired with a 500gm hardeneran elite solution for lavish surface finishing and stone resining. Crafted with 100% purity and a transparent finish, this industrial-grade epoxy ensures best-in-class results for professionals seeking excellence in application and durability. The superior mixing ratio (2:1 by weight) delivers optimum bonding and flawless clarity. Explore premium quality in liquid form, suitable for distributors, exporters, importers, manufacturers, retailers, suppliers, traders, and wholesalers across Indiaan excellent choice for advanced industrial and artistic applications.

Unmatched Features for Elite Performance

EPOXY RESIN-10801kg HARDENER 500gm features a transparent, high-purity material ideal for stone resining, netting, and artistic surfacing. Renowned for its excellent physical state and lavish finish, it caters to artisans, craftsmen, industrial applicators, and DIY enthusiasts. The user-friendly mixing process ensures consistent, professional outcomes, making it a favorite among experts seeking elite results and exceptional durability in demanding applications.

Secure Shipping and Supply Assurance

Our supply chain ensures swift and secure shipping of EPOXY RESIN-10801kg HARDENER 500gm throughout Indias main domestic markets. With robust order processing, safe packaging, and efficient dispatching, customers receive products in excellent condition. Packaging is tailored to maintain product integrity during transit, emphasizing careful handling. We pride ourselves on reliable order fulfillment and seamless, timely deliveries for wholesalers, retailers, and end-users alike.

Unmatched Features for Elite Performance

EPOXY RESIN-10801kg HARDENER 500gm features a transparent, high-purity material ideal for stone resining, netting, and artistic surfacing. Renowned for its excellent physical state and lavish finish, it caters to artisans, craftsmen, industrial applicators, and DIY enthusiasts. The user-friendly mixing process ensures consistent, professional outcomes, making it a favorite among experts seeking elite results and exceptional durability in demanding applications.

Secure Shipping and Supply Assurance

Our supply chain ensures swift and secure shipping of EPOXY RESIN-10801kg HARDENER 500gm throughout Indias main domestic markets. With robust order processing, safe packaging, and efficient dispatching, customers receive products in excellent condition. Packaging is tailored to maintain product integrity during transit, emphasizing careful handling. We pride ourselves on reliable order fulfillment and seamless, timely deliveries for wholesalers, retailers, and end-users alike.

FAQs of EPOXY RESIN-10801kg HARDENER 500gm:

Q: How should EPOXY RESIN-10801kg HARDENER 500gm be mixed for best results?

A: Mix 2 parts of epoxy resin (Part A) with 1 part of hardener (Part B) by weight. Thoroughly combine both components before applying them to the cleaned and dried surface.Q: What applications are suitable for this epoxy resin and hardener system?

A: This system is ideal for stone resining, netting, surface repairs, and artistic projects that require a high-purity, transparent, and durable finish.Q: When can the resined surface be polished?

A: You may polish the surface after 24 hours, depending on the ambient temperature and conditions, for optimal shine and smoothness.Q: Where should the product be stored to maintain effectiveness?

A: Store the product away from heat and direct sunlight and always ensure the temperature remains above 1015C (5059F) to ensure the resin cures properly.Q: What are the benefits of using this specific epoxy resin system?

A: Users benefit from exclusive clarity, excellent bonding strength, and a lavish, durable finish, making it suitable for elite industrial and decorative applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Penetrating Sealers Category

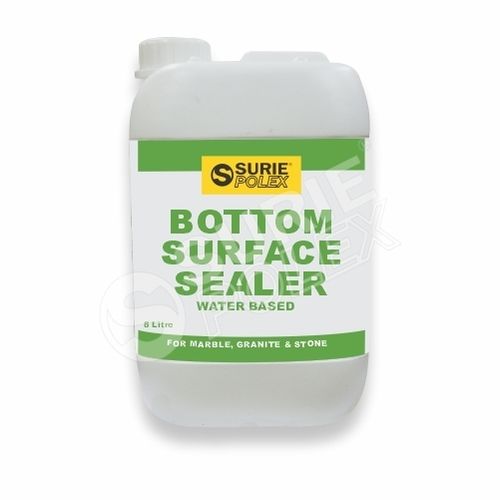

5 Ltr Bottom Surface Sealer

Price 3188.00 INR / Piece

Minimum Order Quantity : 10 Liters

Physical State : Liquid

Purity : 98%

Grade : Industrial grade

Other Names : Surface Protective Sealer

Stone Sealer 5Litre

Price 1602.00 INR / Piece

Minimum Order Quantity : 50 Pieces

Physical State : Liquid

Purity : 100%

Grade : Industrial Grade

Other Names : Floor Sealers

Stain Repellent Sealer 1Ltr

Price 1500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Physical State : Liquid

Purity : 100%

Grade : Industrial Grade

Other Names : Stain Repellent Sealer

TRUKOLOR A-180 1Litre

Price 1350.00 INR / Piece

Minimum Order Quantity : 1 Liter

Physical State : Liquid

Purity : 100%

Grade : Industrial

Other Names : FLOOR SEALER

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS